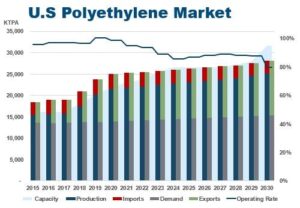

The plastic resin distribution industry plays a critical role in the global supply chain of plastics. This industry is responsible for sourcing, buying, and distributing various plastic resins, the raw materials used to produce plastics. Importantly, distribution companies act as intermediaries between manufacturers, processors, converters, and end-users. These companies offer various services, including warehousing, logistics, transportation, and technical support. The global plastic resins market is projected to grow at a compound annual growth rate of 4.5% from 2022 to 2030.

What is Plastic Resin?

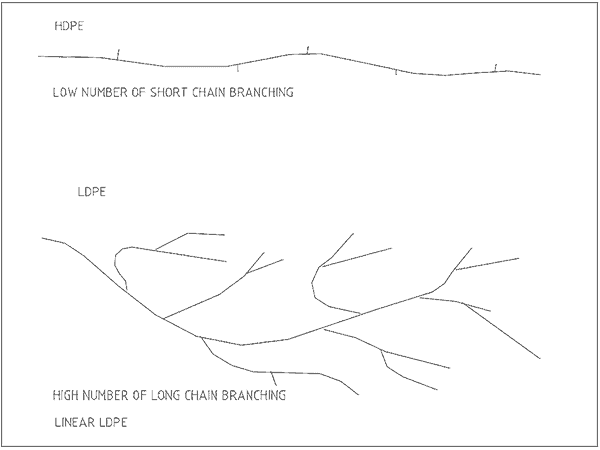

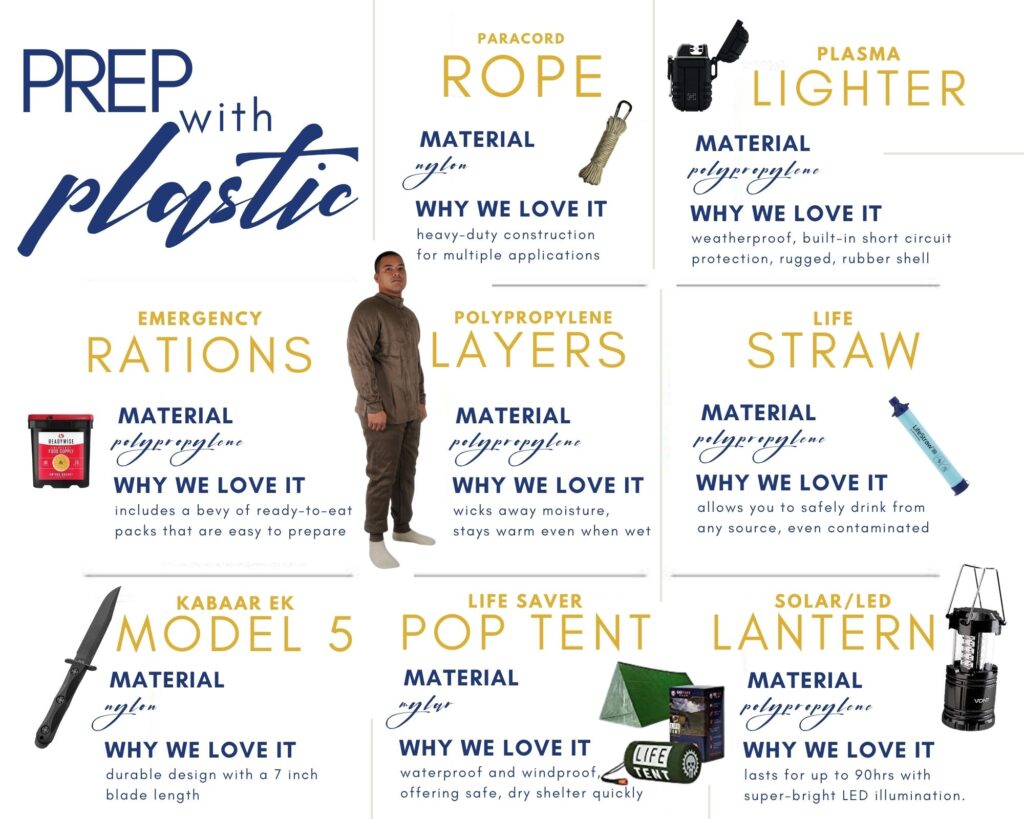

Plastic resin refers to the raw material used to create plastic products. Resins are synthetic materials made from various polymers, which are long chains of molecules with similar structures. In fact, Statista reports, “The demand for plastics has grown exponentially since it first became commercially available more than half a century ago. Since then, plastics have become massively important materials that are used in all walks of life, from electronic products, textiles, automobiles, and construction. Innovations in plastics have also revolutionized the medical sector.” The most common types of plastic resins used in the industry include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate (PET).

What Does a Plastic Resin Distribution Company Do?

Primarily, a plastic resin distribution company acts as a bridge between plastic resin manufacturers and end-users. These companies buy plastic resin in large quantities from manufacturers and store them in warehouses. Then, they sell smaller amounts of resin to processors, converters, and end-users. The distribution process involves several components, including the following:

- Sourcing: Plastic resin distribution companies source their raw materials from a variety of manufacturers around the world. They must ensure that the plastic resin they purchase meets their customers’ quality and quantity requirements.

- Warehousing: Once the plastic resin is sourced, it is stored in a warehouse until it is sold to the end users. Plastic resin distribution companies must ensure the warehouse facilities are suitable for storing the specific types of plastic resin they are handling.

- Logistics: Once a customer orders, the plastic resin distribution company must ensure that the order is fulfilled and delivered on time. This process involves managing transportation logistics and coordinating with freight companies to ensure timely delivery.

- Technical Support: Plastic resin distribution companies provide technical support to their customers to ensure that they use the plastic resin correctly. This suport often includes assistance with product selection, testing, and troubleshooting.

Who are the Customers of Plastic Resin Distribution Companies?

Included in their list of customers, plastic resin distribution companies serve a varied group. To name a few, they serve plastic processors, converters, and end-users. Plastic processors and converters are companies that take plastic resin and convert it into finished products. On the list of finished products you find common items such as plastic bottles, bags, and containers. Conversely, on the uncommon end, you find highly specialized items like medical devices. End-users, such as automotive manufacturers and construction companies, use plastic products as part of their manufacturing process.

In short, the industry is critical to the global plastics industry. With plastic resin distribution companies, the production of plastic products is much more manageable. Manufacturers deal with the logistics of shipping and storing raw materials. By acting as intermediaries between the petrochemical plants and the manufacturers, plastic resin distribution companies make it easier for businesses to access the raw materials they need to produce their products in a timely and budget-conscious manner.

Frequently, polypropylene is melt-spun into fibers. “Polypropylene fiber is a major factor in home furnishings such as upholstery and indoor-outdoor carpets. Numerous industrial end uses exist as well, including

Frequently, polypropylene is melt-spun into fibers. “Polypropylene fiber is a major factor in home furnishings such as upholstery and indoor-outdoor carpets. Numerous industrial end uses exist as well, including

The Target Zero icon will be seen by guests on shelves in-store, and through a dedicated online experience at

The Target Zero icon will be seen by guests on shelves in-store, and through a dedicated online experience at