Shaping the World Through Polyethylene

(Article 1 of 2 in the series)

With the shake of a hand, in the 1967 movie The Graduate, Mr McGuire gives Benjamin some career advice: “I want to say one word to you. Just one word… plastics. That’s where the future’s at!” If Mr. McGuire only knew how right he was. Some 400 million metric tons of plastics come into the world annually, from shoelaces to learjets. And plastic wouldn’t hold its position of prominence without polyethylene.

Polyethylene Stands Out: Shaping Our World

What is polyethylene?

Polyethylene stands out as the supreme plastic – most produced in the world. Many people, encountering plastics in every facet of their everyday lives, assume that all plastics are the same. Plastic is plastic, right? In truth, hundreds of polymers exist, but only a few touch our lives on a regular basis. Polyethylene, though, stands out as special.

In our times, petrochemical facilities produce 150 million tons of polyethylene annually. This accounts for 37 percent of the total plastics market. As the largest-volume polymer, polyethylene fills needs around the globe. Polyethylene, with its chemical resistance and ease of fabrication, enjoys wide popularity. Its molecular structure provides the key to its versatility. Safe for food and drink, highly recyclable, lightweight, shatter resistant, and inexpensive, polyethylene does it all. Advances in technology continue to improve its functionality, making polyethylene the most efficient of all uses of petroleum and natural gas.

The Chemistry of Polyethylene Stands Out

Ethylene (C2H4) is a gaseous hydrocarbon commonly produced by the “cracking” of ethane, which can be distilled from petroleum. Ethylene molecules include two methylene units (CH2) linked together by a double bond between the carbon atoms—a structure represented by the formula CH2=CH2. Under the influence of polymerization catalysts, the double bond can be broken.

Molecular Structure

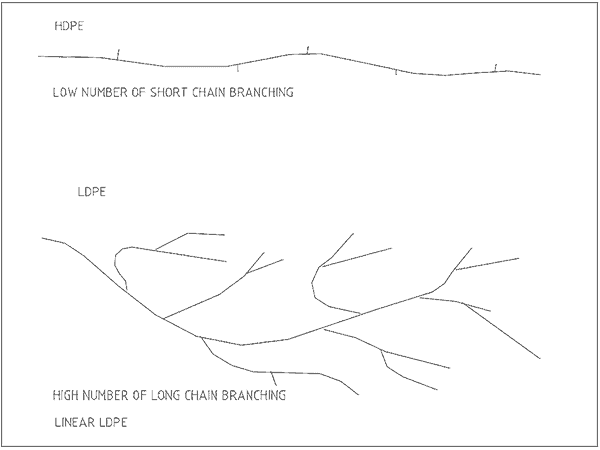

This simple structure, repeated thousands of times in a single molecule, holds the key to the properties of polyethylene. The long, chainlike molecules, in which hydrogen atoms connect to a carbon backbone, assume both linear and branched forms.

Chemists refer to the branched versions as low-density polyethylene (LDPE). They refer to the linear versions as high-density polyethylene (HDPE).The carbon chain length and extent of branching greatly affect the properties of the plastic. The illustration below contrasts the differing structures of the macromolecules for LDPE and HDPE. The amount of side-chain branching varies the closeness that molecules can come together. Closely compact chains give more rigid and solid plastics.

The Three Most Commonly Used Types of Polyethylene: PETE, HDPE, and LDPE

Collectively, polyethylene, the most common plastic in the world, falls into three classifications: Polyethylene Terephthalate, High Density Polyethylene, and Low Density Polyethylene. Here’s how they vary, just slightly, from one another:

Polyethylene Terephthalate – known as PETE, PE, or simply polyethylene, Polyethylene Terephthalate carries the reputation of being the most common plastic on earth. Lightweight and strong, it plays a vital role in the production of fabric and in the packaging of foods. Polyethylene can be manufactured in varying densities. Each different density of polyethylene gives the final plastic unique physical properties.

High Density Polyethylene (HDPE) – More rigid than both LDPE and PETE, HDPE plastic sheeting works ideally for water and sewer piping, snowboards, boats, roller chain sprockets, rebar, pulleys, and more. It ranks as one of the most popular materials used in thermoplastic engineering.

Low Density Polyethylene (LDPE)– This density of polyethylene exhibits ductility, and forms a softer, clearer, more flexible version of HDPE. Often used as a liner inside beverage cartons, LDPE excels as the basis for corrosion-resistant work surfaces and other products. Still can’t picture it? Think plastic bags and bubble wrap. Both courtesy of LDPE.

Putting Polyethylene to Use

The Vast Applications of Polyethylene

As the most widely used plastic in the world, polyethylene serves as the raw material of products ranging from clear food wrap to detergent bottles to automobile fuel tanks. When it is slit or spun into synthetic fibers or otherwise modified, it takes on the elastic properties of rubber.

Polyethylene most often finds usage in beverage bottle plastics. Though hundreds of applications for PE exist, polyethylene furnishes the perfect material for water bottles and food packaging. According to the International Bottled Water Association, bottled water ranks as the most consumed beverage in the United States (by volume). According to a report of the International Bottled Water Association (IBWA), the per capita consumption equals more than 43 gallons of bottled water, a figure that is still rising. With trends like these, the demand for PE in bottled water packaging will surely keep increasing.

But don’t forget – polyethylene shows up in more than just bottles and packing. It fills a variety of applications. You undoubtedly encounter them at the supermarket. But other encounters abound. PE goes into tennis balls, bulletproof vests, and even glitter. It even makes chewing gum chewable. Believe it or not, chewing gum incorporates plastic. Manufacturers typically call it their “gum base” but if you dig a little deeper, you find that this base includes polyethylene.

polyethylene in vests tennis balls glitter.jpg 233 KB View full-size Download

We also encounter polyethylene in our toys, pipes, fittings, cable jacketing, and insulation. PE has come a long way. Globally, plastic food packaging accounts for 45 percent of the $1 trillion global plastic market.

Polyethylene Stands Out Today

Today, the food and beverage market comprises the largest source of demand for PET packaging. More than 70 percent of the soft drinks in the global market come packaged in PET plastic bottles. This means only 30 percent get packed with other materials, like glass and paper-based cartons, underscoring why products made from polyethylene stand out. In fact, attempting to replace plastics with an alternatives that perform the same function would increase environmental costs from $139 billion to $533 billion annually. Plastic enables us to do more with less. Polyethylene plastics are used in nearly every walk of life from everyday items to the unusual.

Additionally:

- Statistics show that 100 million plastic bags get used in the United States each year

- In the United States, the average office worker uses around 500 disposable cups per year

- The plastic bottles and containers market stood at $39 billion in 2020, and observers expect it to reach a value of $50 billion by 2025

Bringing it All Together

Born from a scientific fluke, polyethylene has truly proven to be just as permeable and moldable as early indications suggested. The substance permeates, molds, and changes the world we live in daily. As the sun rises on tomorrow, the future looks bright. That is, of course, if we hang on to that one, simple, yet powerful keyword Mr. McGuire alluded to in The Graduate: plastics. It really is where the future’s at.