Common questions asked about polypropylene often revolve around its properties, uses, advantages, and disadvantages. Here are some frequently asked questions about polypropylene:

- What is polypropylene (PP)?

- Polypropylene is a thermoplastic polymer that is widely used in various industries. It is known for its versatility, durability, and resistance to chemical and moisture exposure.

- What are the key properties of polypropylene?

- Polypropylene is lightweight, strong, resistant to moisture, chemicals, and UV radiation. It has a high melting point, good electrical insulation properties, and is relatively low-cost.

- What are the common uses of polypropylene?

- Polypropylene is used in a wide range of applications, including packaging materials, automotive components, medical devices, textiles, bottles, and household products like containers and furniture.

- Is polypropylene recyclable?

- Yes, polypropylene is recyclable, and it is commonly used in recycling programs. It can be melted down and reused in various products.

- What are the advantages of using polypropylene?

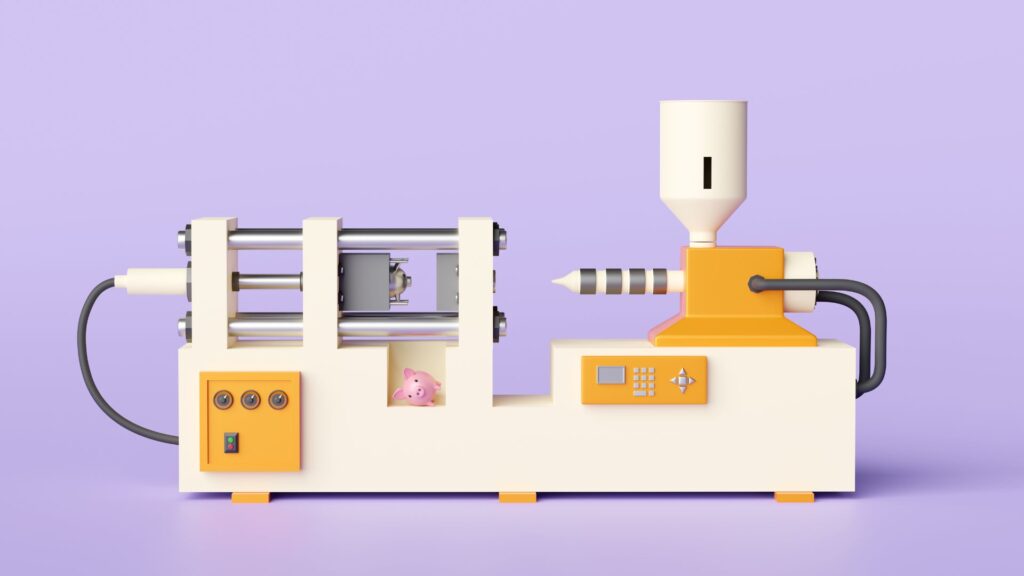

- Advantages of polypropylene include its low cost, high chemical resistance, lightweight nature, and ease of processing in manufacturing.

- Are there any disadvantages to using polypropylene?

- Some disadvantages include its relatively low heat resistance compared to other plastics, susceptibility to UV degradation, and potential for warping when exposed to high temperatures.

- Can polypropylene be used for food storage?

- Yes, polypropylene is often used for food storage containers and packaging because it is safe, resistant to moisture, and does not react with most food substances.

- Is polypropylene safe for medical applications?

- Polypropylene is commonly used in medical devices and equipment because it is non-toxic, non-reactive, and has good sterilization capabilities.

- What are the differences between polypropylene and other plastics like polyethylene and PVC?

- Polypropylene differs from other plastics in terms of its chemical structure, properties, and common applications. Polyethylene is known for its flexibility, while PVC is often used for its rigidity and electrical insulation.

- How can polypropylene be welded or joined?

- Polypropylene can be joined through various methods, including hot plate welding, ultrasonic welding, and solvent welding, depending on the specific application and desired bond strength.

- Is polypropylene suitable for outdoor applications?

- Polypropylene is durable and resistant to moisture and chemicals, making it suitable for some outdoor applications. However, it may degrade over time when exposed to prolonged UV radiation.

These are some common questions about polypropylene, but the specific questions may vary depending on the context and the individual’s level of familiarity with the material.