Almost every product in the 21st century requires plastic in one form or another. The invention of plastic endures as one of the greatest achievements of science and industry. Since its accidental discovery it has evolved into the material of our lives. The car seat you strap your child into, the point-of-sale system your Starbucks barista swipes your card on: both incorporate plastic. The same with the car you drove to get to Starbucks and even the very shirt on your back. Plastics have gone from being “just plastic” to being one of the single greatest contributions to life as we know it today.

THE ACCIDENTAL DISCOVERY

Missed Details and Accidental Success

In 1933, while running experiments on different elements, two chemists accidentally created one of the biggest assets of the 20th and 21st centuries. It all came with a little help from oxygen. Upon applying extremely high pressure to a mixture of ethylene and benzaldehyde, they produced a white, waxy material.

Polyethylene was discovered by accident in 1933 in Northwich, England. The two scientists, Eric Fawcett and Reginald Gibson, working at Imperial Chemical Industries (ICI), stumbled upon this new substance. During their experiments, a test vessel leaked, leaving trace amounts of oxygen in their ethylene samples. The oxygen acted as an initiator, creating a substance previously unknown to man. Life as they knew it would soon drastically change.

Because the reaction had been initiated by trace oxygen contamination in an apparatus, the experiment was difficult to reproduce at first. It was not until 1935 that another chemist working for ICI, Michael Perrin, pushed matters further. He advanced this accidental process into a reproducible high-pressure synthesis for polyethylene. That process became the basis for industrial low-density polyethylene (LDPE) production, beginning in 1939. The following image is a pillbox made from the first pound of polyethylene produced at the ICI. This box was a commemorative gift presented to a member of the research team. (First polyethylene pillbox – Photo credit: Wikipedia.) Interestingly enough, polyethylene is still used for holding pills today.

Polyethylene Timeline

From WWII to Everyday Use

Before there was the “plastics industry,” there was just plastic. For decades, plastic provided abundant goods that exhibit qualities of being durable, light weight, and inexpensive. As American industry grew, the plastics industry grew with it, helping propel the United States into an industrial giant.

POLYETHYLENE IN WWII

1939- 1945:Military Secrets and Banned Substances

The war that changed the world also heralded the era of plastics. During World War II, polyethylene was a military secret. First used as an underwater cable coating, polyethylene came to serve a critical role in insulating material for military radar insulation. Polyethylene’s light weight and thin structure made it possible to place radar equipment on airplanes.

Additionally, because polyethylene was found to have low-loss properties at high frequency radio waves, commercial distribution in America was suspended once the war broke out.

Polyethylene Post WWII

The 1940s-1980s

After the war, polyethylene became a tremendous hit with consumers. It became the first plastic in the United States to sell more than a billion pounds a year. The landmark breakthrough in the commercial production of polyethylene began with the development of catalysts that promoted the polymerization at mild temperatures and pressures. As commercial production boomed, the American people took notice.

The Feachem Totem

2009

George Feachem, a young chemist, was on duty that fateful night of accidental success. Feachem witnessed the discovery first hand, but he never could have imagined the impact it was to have on the world.

George Feachem died in the late 1970s. It wasn’t until 2009 that his grandson, Chris Browning, discovered a small, triangular, plastic medallion inside an old wallet found in a drawer of Feachem’s possessions. Intriguingly, it bore the inscription “Dec 1938.” The medallion was attached to a small brass clasp engraved with his initials, “G.F.” After making enquiries, the family discovered that George’s secret keepsake was a sample of the very first ton of polyethylene ever produced. Mr. Browning has since submitted this first piece of polyethylene to the BBC History of the World project in recognition of his grandfather’s work.

Polyethylene Today

In 1995, Jeffrey Meikle authored his book American Plastic: A Cultural History. In it, Meikle spoke candidly, stating “The ever-expanding proliferation of consumer goods has created an inflationary culture, and plastic has become the material of choice for this never-ending expansion. It is inexpensive, flexible, and less solid than wood or steel. It’s free of traditional preconceptions regarding its use and can be molded into any shape a restless drive for novelty might conceive… Plastic not only offered a perfect medium for this material proliferation, it conceptually embodied and stimulated it.”

Plastic packaging is the perfect example of material stimulation, just as Meikle observed. Among consumers, plastic packaging enjoys great popularity versus alternative packaging. Because of plastic’s light weight and ease of handling, manufacturers favor it. Plus, with plastic, production costs go down. Implementation of PET and plastic packaging leads to 90 percent weight reduction compared to glass, allowing a more economical transportation process.

Into the Future

The Polyethylene of Tomorrow

Polyethylene has propelled us through the years with unimaginable success. Success that shows no signs of stopping. In 2019 the beverage industry adopted recyclable PET (rPET), which led to a tremendous increase in production thanks to major participants such as PepsiCo and Coca-Cola. In July 2019, Coca-Cola announced that their subsidiaries would be embracing rPET as well. Glacéau Smartwater, Honest Tea, and Chaudfontaine brands, as well as HBC water (a Swiss marketed product), will now be bottled in recycled polyethylene terephthalate.

And the beverage industry isn’t the only industry to make big mergers with polyethylene products. In 2020, BP PLC, a significant player in the oil and gas industry, developed an innovative enhanced recycling technology. This technology is capable of processing PET plastic waste, which too often goes unrecycled. BP plans to complete the pilot plant in the United States by 2023.

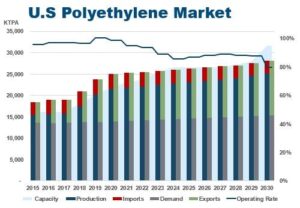

As of this year, the United States is currently producing 6 million more tons of PE per year than it did just five years ago. And yet, there is still room to grow. Five years ago, polyethylene represented one-third of domestic production; today it accounts for half.

Bringing it all together

Looking back and looking forward, we can’t escape the fact that plastics continually occupy the epicenter of economic growth. Our reliance on them as a society underscores the three basic, elemental things plastics do: assist, protect, and provide. They assist us in our daily lives, protect our food through packaging, and provide endless opportunities for tomorrow.