A recent study proves what we here at Lone Star Chemical already knew: the prospects for PLA and other bio-plastics are bright and headed for bigger things.

Worldwide, PLA and its bio-plastics kin, taken as an industry, are expected to top $7 billion in sales volume by 2027. That’s right—a scant five years from now, the bio-polymers business will have increased some 65 percent over its current volume of $4.3 billion.

The study, which was released earlier this year with the formidable title of “Biodegradable Plastics Market Size, Global Forecast 2021-2027, Industry Trends, Impact of COVID-19, Opportunity Company Analysis,” stated that environmentally friendly plastics alternatives have boomed globally.

As sources as GlobeNewswire.com have reported, biodegradable plastics are one set of materials that have become a popular replacement for conventional plastics as consumers demand green options to align with the environment.

“Biodegradable plastic degrades under biological [mainly microbial] action with [little if any] chance of hampering the natural environment,” Globe Newswire stated. “Moreover, the awareness of conventional plastic’s harmful impact on the environment has also supported the global market for biodegradable plastics.”

Biodegradable plastics increasingly are becoming the choice for companies seeking an alternative to conventional plastics. As Globe Newswire observed, the pandemic of 2020-2022 caused a demand spike for packaging for food, pharma, and PPE. “Companies have endeavored [to find] biodegradable alternatives for food packaging and single-use cutlery,” the news outlet said.

“Numerous biodegradable and compostable plastics are bioplastics produced from plants rather than fossil fuels,” according to Globe. “There are many options, such as packaging, agriculture, and consumer goods depending on their application. Biodegradable plastics can be split down by microbes, as well as crushed up and converted into biomass, water, and carbon dioxide.”

Within the field of biodegradable plastics, a few are most popular, these being Polybutylene Adipate Terephthalate (PBAT), Polybutylene Succinate (PBS), Polylactic Acid (PLA), Polyhydroxyalkanoate (PHA), and Starch Blends.

Bio-Plastics and the Future

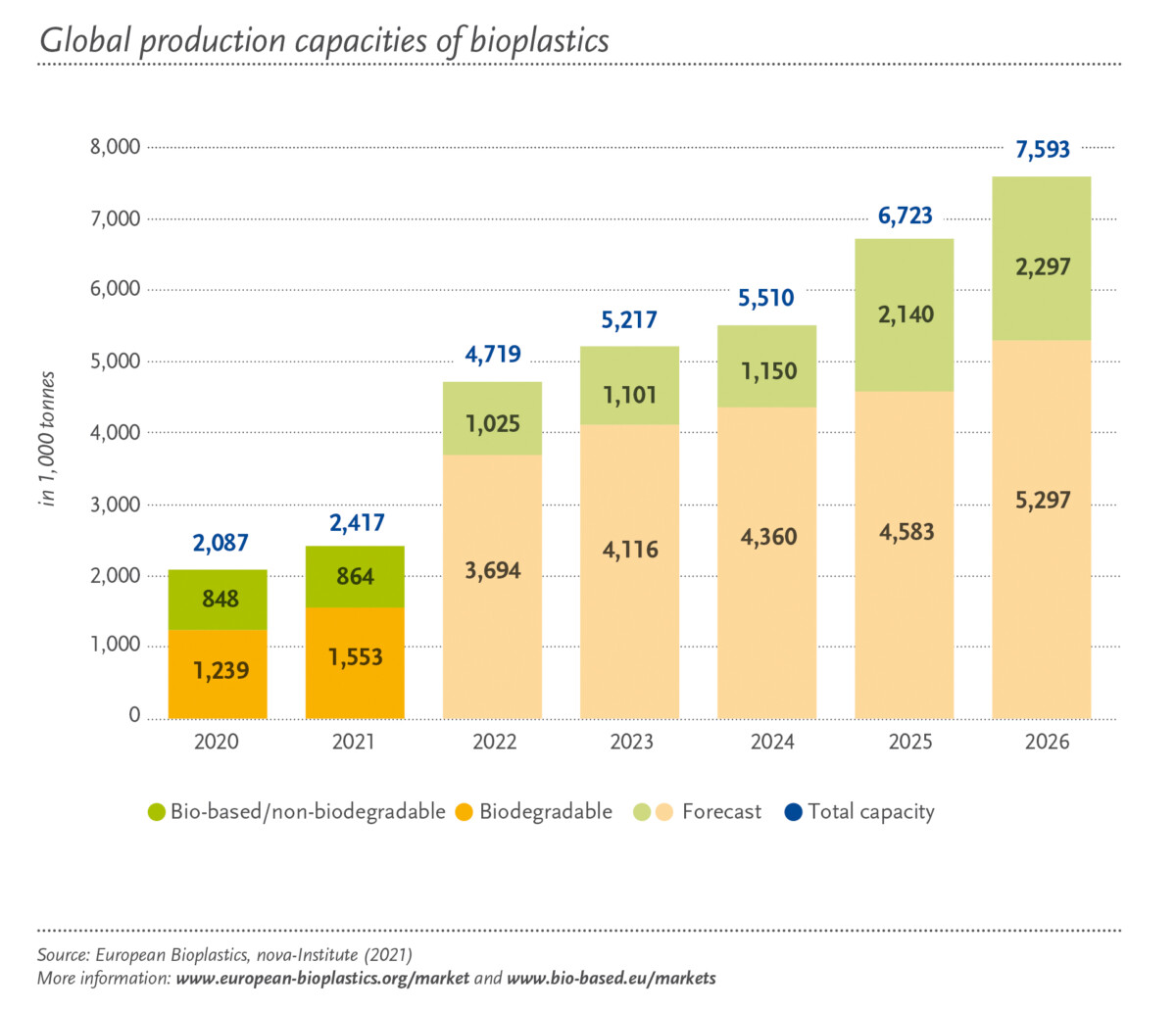

In a separate study, researchers concluded that, globally, bioplastics production (as opposed to dollar volume, discussed above) will more than triple within the next five years. The findings were based on research compiled by bioplastics association European Bioplastics (EUPD), in cooperation with the Nova Institute in Germany.

EUBP presented the outlook at the 16th EUBP Conference on Dec. 1. A Dec. 22 article by OFI Magazine(ofimagazine.com) covered the event. OFI cited a remark by EUPD chairman Francois de Bie, when the chairman observed that the importance of a 200 percent growth rate within the next five years cannot be overstated.

“Before 2026, the share of bioplastics in the total global production of plastics will pass the 2 percent mark for the first time,” de Bie stated, according to OFI.

The magazine stated that “Biodegradable plastics, including PBAT, PLA, and polybutylene succinate (PBS), currently account for slightly more than 64 percent (1.5 million tons) of global bioplastics production, according to EUPD’s report.

“Packaging remained the largest field of application for bioplastics, but the report showed that bioplastics materials were also being used in many other industries, with some sectors, such as consumer goods, continuing to moderately increase their relative share.”

In concluding the discussion, the magazine quoted EUPD managing director Hasso von Pogrell. “We will see an impressive increase in bioplastics production over the next [several] years. This also requires the expansion of production facilities,” EUPD managing director Hasso von Pogrell said. “This way, our industry will be able to respond to the growing demand for bioplastics.”

The full story can be found at OFI‘s website.

PLA and its “Total” Picture

Total Energies is a petrochemical partner of Lone Star, and Total is a leader in the production of both PLA and numerous other bio-plastics.

Further, Total Energies has shown itself to be an effective promoter, popularizer, and advocate of the earth-friendly new plastics offerings.

The company posts insightful details about PLA, for instance, on their TotalEnergies-Corbion.com site. We share some quotes below:

“PLA or Polylactic Acid is a range of unique bio-plastics which is both bio-based and biodegradable. In the right environment they will serve as a source of food for micro organisms and fungi. After the biodegradation process is completed only natural and harmless substances like water, CO2 and compost will remain behind. For PLA the biodegradation process will go relatively fast in industrial composting facilities and will take longer to complete in less biologically active environments. Besides composting, PLA bioplastics also offers additional end-of-life options like mechanical and chemical recycling.”

PLA Has High Heat Resistance

Says Total: “PLA bio-plastics can already be found in a broad range of established markets, like fresh food packaging, organic waste bags, food serviceware, tea bags, durable consumer products, toys, 3D printing,and non wovens. Most PLA bio-plastics of the past had the major drawback that they could not withstand increased temperatures. However, TotalEnergies Corbion has developed a high heat resistant solution for PLA-based bioplastics.”

PLA Has a Reduced Carbon Footprint

PLA bioplastic enable products to be produced with a high biobased content and a reduced carbon footprint. In case of Total Energies’ Luminy® PLA, the company (and Lone Star, its distributor) is pleased to observe that Luminy® gives its users a 75 percent reduction in carbon footprint compared to most traditional fossil-based plastics. PLA is produced from renewable feedstocks like sugarcane, corn, sugar beet, and cassava.

More information can be found at Total Energies’ website.

PLA is Pure and Natural

Lone Star Chemical’s CEO, Kip McAllister, has made it a company emphasis to increase Lone Star’s commitment to the marketplace’s adoption of bio-plastics. To that end, he refers many customers to another of Lone Star’s distributor-partners, Bio-Based Polymers (https://bio-basedpolymersusa.com). Says McAllister: “One of the product lines sold through Bio-Based Polymers is PLA. It’s a product that looks much like normal plastic, feels like normal plastic, but is made from sugar cane.”

Plastics Make it Possible

One of Lone Star’s favorite sources for plastics information is the website found at PlasticsMakeItPossible.com. And, yes, Plastics Make It Possible has also gotten on the bio-plastics bandwagon, with some great content that speaks well to the general public. Again, we share some excerpts:

“One point of general confusion [when the discussion turns to bio-plastics] is the inevitable desire to compare a molecule derived from natural gas/oil/coal to the same molecule derived from a ‘bio’ source. Many people believe these two molecules surely must have different properties and behave differently in the environment. Well … In reality, identical chemical structures behave the same.

“Here’s an example for plastics. One of the primary feedstocks for plastics is ethylene, produced in North America primarily from natural gas. (Ethylene derived plastics are used for all sorts of everyday products, from milk jugs to carpeting to fleece jackets.)

“Ethylene also is created naturally by plants. Ever wonder why a banana ripens faster in a paper bag? The banana actually creates and emits ethylene gas, which helps speed the ripening process—placing the banana in the bag traps more ethylene gas.”

Ethylene is Ethylene

Again, quoting from Plastics Make It Possible:

“Does the “bio” ethylene have different properties than the ethylene derived from natural gas? No. Ethylene is ethylene, regardless the source. Ethylene’s structure (C2H4) is always exactly the same… just like good old water’s structure (H20) is always the same.

Will plastics derived from different ethylene sources have different properties? No. The original source of the ethylene is irrelevant to plastics (and to bananas).

For more from Plastics Make It Possible, visit their site.

One Word. Plastics.

That oft-quoted line from the motion picture The Graduate might be ripe for some modification in the 2020s, giving the direction things are headed.

One word. Bio-plastics.

An article by Tony Rogers for Creative Mechanisms (CreativeMechanisms.com) accentuates the positives attached to bio-plastics, while the products themselves eliminate many of the negatives of traditional oil-and-gas-based petrochemical plastics.

As Rogers states, “Polylactic Acid (PLA) is different than most thermoplastic polymers in that it is derived from renewable resources like corn starch or sugar cane. Most plastics, by contrast, are derived from the distillation and polymerization of nonrenewable petroleum reserves. Polylactic Acid is biodegradable and has characteristics similar to polypropylene (PP), polyethylene (PE), or polystyrene (PS). It can be produced from already existing manufacturing equipment (those designed and originally used for petrochemical industry plastics). This makes it relatively cost efficient to produce. Accordingly, PLA has the second-largest production volume of any bioplastic (the most common being thermoplastic starch).”

Polylactic acid (PLA) is the source material for a rapidly expanding array of products and applications. As Rogers observes, the most common uses include plastic films, bottles, and biodegradable medical devices (e.g. screws, pins, rods, and plates that are expected to biodegrade within 6-12 months).

“PLA constricts under heat and is thereby suitable for use as a shrink wrap material,” Rogers writes. “Additionally, the ease with which Polylactic Acid melts allows for some interesting applications in 3D printing. On the other hand, its low glass transition temperature makes many types of PLA (for example, plastic cups) unsuitable to hold hot liquid.”

What Makes PLA So Special?

Here’s where the PLA picture gets even more promising. The designation PLA is actually a collective term for a family of bio-chemicals. Polylactic acids include Racemic PLLA (Poly-L-lactic Acid), Regular PLLA (Poly-L-lactic Acid), PDLA (Poly-D-lactic Acid), and PDLLA (Poly-DL-lactic Acid). According to Rogers and Creative Mechanisms, each of these variants has slightly different characteristics but they are similar in that they are produced from a renewable resource (lactic acid: C3H6O3) as opposed to traditional plastics, which are derived from nonrenewable petroleum.

Says Rogers: “PLA production is a popular idea as it represents the fulfillment of the dream of cost-efficient, non-petroleum plastic production. The huge benefit of PLA as a bioplastic is its versatility and the fact that it naturally degrades when exposed to the environment. For example, a PLA bottle left in the ocean would typically degrade in six to 24 months. Compared to conventional plastics (which in the same environment can take several hundred to a thousand years to degrade) this is truly phenomenal. Accordingly, there is a high potential for PLA to be very useful in short lifespan applications where biodegradability is highly beneficial (e.g. as a plastic water bottle or as a container for fruit and vegetables). Of note, despite its ability to degrade when exposed to the elements over a long time, PLA is extremely robust in any normal application (e.g. as a plastic electronics part).”

Find the rest on Creative Mechanisms’ site.