Kip McAlister, president and CEO of Lone Star, took time with an interviewer to answer questions about Lone Star’s logistics, operations, and the defining traits of the company.

Interviewer: What is an advantage that a customer might get from doing business with Lone Star Chemical?

Kip: We communicate very well with our customers. We stay in touch and we respond quickly. When you call us, a human being answers the phone 90 percent of the time. And we keep product inventoried in locations that are generally in close proximity to a customer, wherever they might be in the country. That means we can get a shipment to the customer quickly, when speed is of the essence.

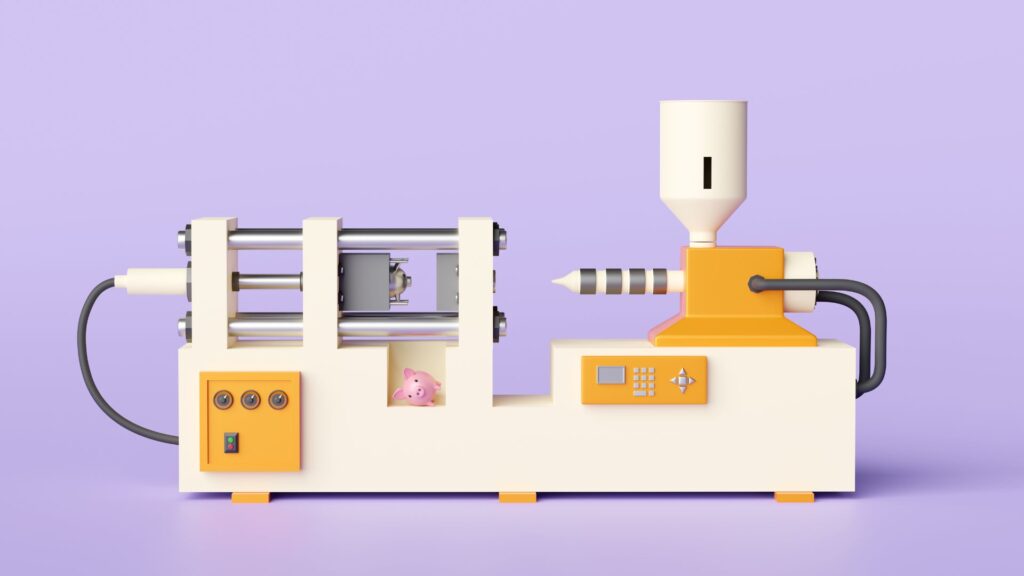

Interviewer: What exactly do you sell?

Kip: We sell polypropylene. Also polyethylene, which will probably become our biggest product here very quickly. And then we sell polystyrene. And repro. We also have another company that we just started in January of 2020 that does bio-friendly products. There’s a big push for environmentally friendly materials, so we’re doing that as well. The new company called Bio-Based Polymers. One of the product lines sold through Bio-Based Polymers is PLA. It’s a product that looks much like normal plastic, feels like normal plastic, but it is made from polylactic acid, which is made from sugar cane.

Interviewer: What are most other polymers and resins made from?

Kip: They are refined from crude oil. That’s one way to get the feedstocks. The other way that it can be done now is with natural gas. But not all [plastics] products can be created that way. Only the polyolefins. The polyolefin consists of polyethylene and polypropylene.

Interviewer: Does Lone Star manufacture any of the plastics it sells?

Kip: No. We don’t make the materials. What we do is buy from the producers [major petrochemical plants] and turn around and resell the materials to companies that use it to make their various products. I think of us more as a help to the producers in moving product. We help them get it moved to areas where they would not normally be active as distributors themselves. They want to sell direct only to the largest customers—the ones who might take 20 railcars at a time. We take shipments that big ourselves, but we break it down to smaller allotments and distribute that to our own customer base that we service. We sell to customers all over the country. Our business is distribution.

When we buy in rail car quantities, we either ship it to our warehouse or we can also ship a rail car, or more than one, directly to a customer of ours. When we ship to a warehouse, it’s not one that we own, but it’s one that we have contracted with. They receive the shipment there and they will package it for us or prepare it however we want. They can put it in bags or in Gaylord boxes, or they can put it on a rail siding, and we can offload that material into bulk trucks and deliver it to people that have silos. We have several [of these] across the country. We have situated them in locations that we feel are best for servicing multiple customers.

If a rail car is shipped directly to a customer, we will give [the carrier] that customer’s delivery address. And we can even have the big oil companies [the producers] set things up to make a regular delivery straight to that customer for us. We deliver by the truckload, too.

Interviewer: What is a Gaylord?

Kip: A Gaylord is a box. It’s a corrugated cardboard box that will hold 1,500 pounds of plastic. So we call it a Gaylord box.

Interviewer: It’s something you forklift?

Kip: Yes. It has a pallet underneath it and you pick it up with a forklift.

Interviewer: So you say you have product stockpiled at different warehouses or silos across the country?

Kip: Yes. And we’ll sometimes have people call in a panic, saying, ‘Oh my gosh, do you have anything you can give me?’ And of course we do. We pull it from a warehouse and send it to them.

Interviewer: What kind of a staff do you have?

Kip: We have eight salespeople. And then we have two very good customer service people. So we have 10. Actually, we have 11 if you count my father still.

Interviewer: So most people are in sales, then?

Kip: Oh yes, absolutely. That’s what we do.

Interviewer: How can people find you?

Kip: Our main phone number is 888.575.9195. Our headquarters office is at Argyle, Texas. Our website is at LoneStarChemical.com. Anyone who’s interested, please get it touch! We’d love to hear from you.