While the term “extrusion molding” might be unfamiliar to most people, those same people likely know and use many extruded products. Extrusion molding of plastic resins is a manufacturing process that yields various goods, including hoses, pipes, plastic tubing, sheeting, and much more.

To demystify extrusion molding, think of the process as forcing molten plastic material through a die that shapes the plastic.

To extrude means to “thrust or force out.” (Dictionary.com) Melted plastic material gets forced through a die and comes out the other side in a continuous, linear shape. A hose, for instance, might be extruded to any length. The manufacturer can cut the hose to desired lengths.

The Process of Extrusion Molding

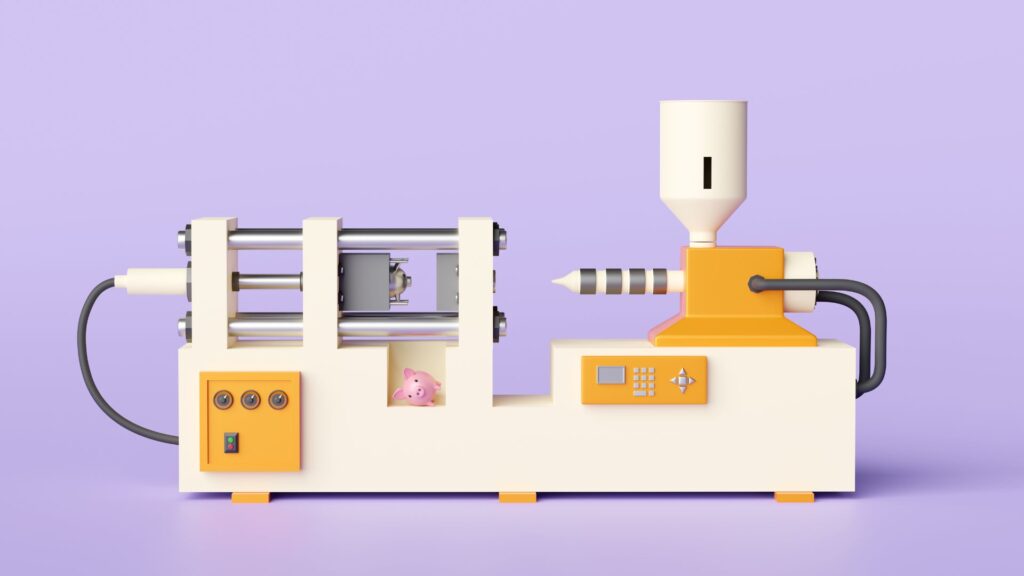

The extrusion molding process begins by feeding plastic resin pellets into a hopper that feeds the material into a heated barrel. As the resin melts, it gets mixed inside the barrel to form a homogeneous molten plastic material. Next, the molten plastic is forced through a shaped opening (the die), which determines the final shape of the extruded product. Finally, after the plastic material exits the dice, it is cooled by water or air and cut to the desired length.

Several plastic resin options exist for extrusion molding. Most commonly, manufacturers choose polyethylene, polypropylene, polystyrene, or PVC. The choice of plastic depends on the application’s specific requirements, such as strength, flexibility, and chemical resistance.

Extrusion Molding vs. Injection Molding

Injection and extrusion molding are two standard methods for manufacturing plastic products. While both processes involve melting plastic resins and shaping them into a specific form, they have significant differences regarding how they operate and the types of products they can produce.

First, injection molding provides a process whereby molten plastic fills a mold cavity under high pressure. The molten plastic, forced into the mold cavity through a nozzle, cools and solidifies to take the desired shape of the product. Injection molding is a highly efficient process capable of producing high volumes of plastic products with consistent quality and precision. Injection molding serves many needs, often used for manufacturing small to medium-sized objects, such as toys, automotive parts, and medical devices.

The versatility of the Extrusion Molding of Plastic Resins

Extrusion molding serves many needs as well. But extrusion molding creates long, continuous forms. The molten plastic gets pushed through the die by a screw or ram, and the material cools and solidifies as it exits the die. Extrusion molding furnishes a highly versatile process that produces products in different shapes and sizes, including plastic pipes, tubes, sheets, and films.

In summary, the main differences between injection molding and extrusion molding are:

- Injection molding produces discrete, three-dimensional objects, while extrusion molding produces continuous, two-dimensional shapes.

- Injection molding produces high-precision, small to medium-sized objects, while extrusion molding makes larger, continuous shapes.

- Injection molding is a higher-pressure process that involves injecting molten plastic into a mold cavity. In comparison, extrusion molding is a lower-pressure process that forces molten plastic through a die.

Advantages and Disadvantages of Extrusion Molding

The advantages of extrusion molding include:

- High production rates: The process can produce large volumes of parts quickly and efficiently, making it an ideal choice for high-volume production runs.

- Versatility: Extrusion molding can produce parts of varying thickness, shape, and size, making it a versatile manufacturing process.

- Low tooling costs: Compared to other molding processes, such as injection molding, the tooling costs for extrusion molding are relatively low.

- Continuous process: Extrusion molding is a constant process, meaning it can produce long lengths of material without interruptions or breaks.

The disadvantages of extrusion molding include the following:

- Limited design flexibility: The shapes that can be produced with extrusion molding are limited by the shape of the die, which can restrict the design flexibility of the process.

- Surface finish: The surface finish of extruded parts can be less precise than other molding processes, such as injection molding.

- Waste material: Because extrusion molding produces a continuous length of material, a significant amount of waste material can be made during the process.

- Material limitations: Not all types of plastics can be extruded, limiting the range of materials used in the process.

Common Products Made from Extrusion Molding

Here are 10 products that are commonly made from extrusion molding of plastic resin:- Plastic pipes and tubes

- Electrical wire insulation

- Window frames

- Vinyl siding for homes

- Plastic sheeting and film

- Plastic profiles, such as edge trim and corner guards

- Drinking straws

- Plastic packaging, such as blister packs and clamshells

- Hoses and tubing for medical and laboratory applications

- Plastic decking and fencing materials