Leave it to the plastics industry—long known for innovation—to come up with a game-changing new direction.

Media attention on “single use plastics”—some of it unfair, but attention nonetheless—has altered the course of the industry in multiple ways. Plastics producers and their business customers have found ways to minimize the negatives of single-use plastics, for one thing. For another, the industry has won favor among environment-conscious consumers by marketing alternative products whose impacts on the environment are diminished, as compared to the products they replace. And of course some offerings have been curtailed altogether by producers, as, again, a way of shrinking the environmental footprint of the plastics industry.

But perhaps the most promising new direction taken by the plastics industry has been its embrace of bioplastics.

Bioplastics are Biodegradable

According to some sources, as much as 8 million tons of plastics finds its way into the planet’s oceans each year. Such pollution poses not just a threat to the environment, but a hazard to health and a serious detriment to quality of life. Clearly, biodegradable plastics could deliver a vital alternative.

They’re beginning to already.

Biopolymers, or bioplastics, are materials for which at least a portion of polymer consists of material produced from biomaterials. These lines represent a new generation of plastics, one that reduces the impact on the environment, both in terms of energy consumption and the amount of greenhouse gas emissions.

And new variations of bioplastics are coming along all the time.

Photo credit: Total Energies

One of the latest of these comes from China, where three scientists have led the engineering on new bioplastics that can be “tailored to needs.”

As reported by ScienceDaily.com, a team led by Jingjing Li and Yawei Liu (Chinese Academy of Sciences, Changchun, China), as well as Bo Wei (First Medical Center of PLA General Hospital) have achieved this first. Their research team has introduced a method for producing of protein-based plastics that are easily processable, biodegradable, and biocompatible, as well as having favorable mechanical properties.

“To do this they developed two lysine-rich proteins and produced them in bacterial cultures,” according to Science Daily. The steps involve “SRT” and “ELP,” the latter being a polypeptide similar to the connective tissue protein elastin. ELP does not have defined folding, which leads to toughness and elasticity. “SRT” consists of ELP plus crystalline segments of a squid protein with a β-sheet structure.

Said Science Daily: “Whether as packaging or toys, mulch films or cars [car components], plastics based on petrochemicals are ubiquitous—demand is rising, and so are the piles of garbage. Bioplastics based on natural materials like starch, or synthetic biomaterials like polylactic acid, have [hitherto] exhibited inadequate durability, biocompatibility, and/or biodegradability in most cases. In addition, they [have] often required complex, energy-intensive processing methods and toxic chemicals.”

The new direction “allows for the production of bioplastics with high mechanical strength at room temperature in any shape desired, and without toxic chemicals or complex processing steps such as liquefaction, extrusion, or blow molding. Their breaking stress exceeds those of many commercial plastics.”

Among the possibilities raised by this breakthrough is the conceivability of toys being producing using this new, nontoxic bioplastic that can be dyed with food coloring.

“This material may also be used to seal wounds, as it has hemostatic effects. Implants were completely broken down within a few weeks.”

The full report can be found on Science Daily’s website.

Bioplastics are Gaining Market Share

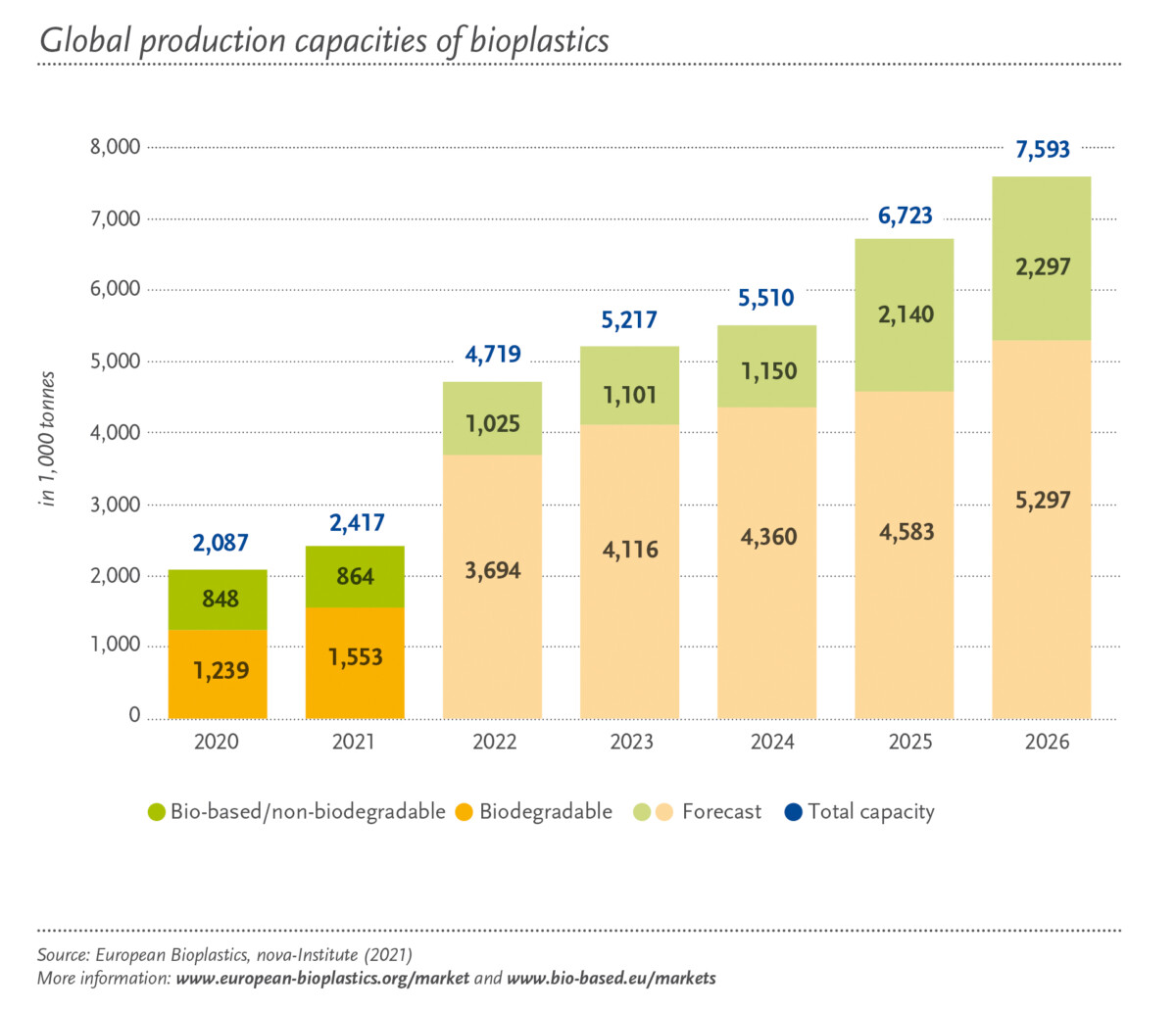

As one source has noted, bioplastics still represent less than one percent of the more than 367 million tons of plastic produced annually. But in contrast to the production volume of conventional plastics, which has experienced a slight decrease, the production volume of bioplastics has grown continuously since their introduction.

The source, European Bioplastics, attributed the trend to a rising demand (for bioplastics in general) helped by the emergence of more sophisticated applications and products.

European Bioplastics cited market data compiled by European Bioplastics in cooperation with the Nova-Institute. These entities contend that global bioplastics production capacities are set to increase from around 2.42 million tons in 2021 to approximately 7.59 million tons in 2026. Hence, the share of bioplastics in global plastic production will pass the two percent mark for the first time. For the European Bioplastic’s report, visit their website.

Utensil Makers Find Advantage in Bioplastics

The market for bioplastic utensils is estimated to grow at a cumulative annual growth rate (CAGR) of more than 5.6 percent, according to a report from River Country News, a Nebraska-based publication.

Expressed as dollars, this change means going from $38 million, which is where the market was at just over a year ago, to some $53 million by 2026.

River Country News stated that bioplastic utensils are different from plastic ones “in that they are derived from natural resources, hence ‘bioplastic,’ whereas utensils made of conventional plastics are constructed from petroleum. Bioplastic utensils come from plants that are found naturally in the environment, such as corn, sugarcane, grass, bamboo, and other such materials. Therefore, because they are constructed of natural materials, they will more easily break down and decompose than traditional plastic will.”

While this development can take years to fully show itself in the broader world of consumer goods, the potential is there. The magazine put it this way:

“As awareness of environment protection strengthens, and as the online shopping phenomenon continues to unfold, people can buy bioplastic utensils online through their smartphone conveniently. More and more people will choose to use bioplastic utensils, not petrochemical plastics utensils.”

See the full story by going to the media outlet’s website.