Rotational molding, also known as rotomolding or rotocasting, is a manufacturing process that involves the use of heat and rotation to produce hollow plastic products. Rotomolding has emerged as a highly effective manufacturing process for a variety of products across diverse industries.

The process is used to create a wide range of items, including toys, tanks, containers, and automotive components. Rotomolding is particularly popular in industries that require large, hollow objects that are durable and lightweight.

Design Flexibility with Rotomolding

One of the primary advantages of rotomolding is its unparalleled design flexibility. Traditional manufacturing processes may have limitations when it comes to creating complex and intricate shapes. Rotomolding, however, allows for the production of products with intricate designs, varying wall thicknesses, and undercuts, enabling manufacturers to bring innovative and unique concepts to life.

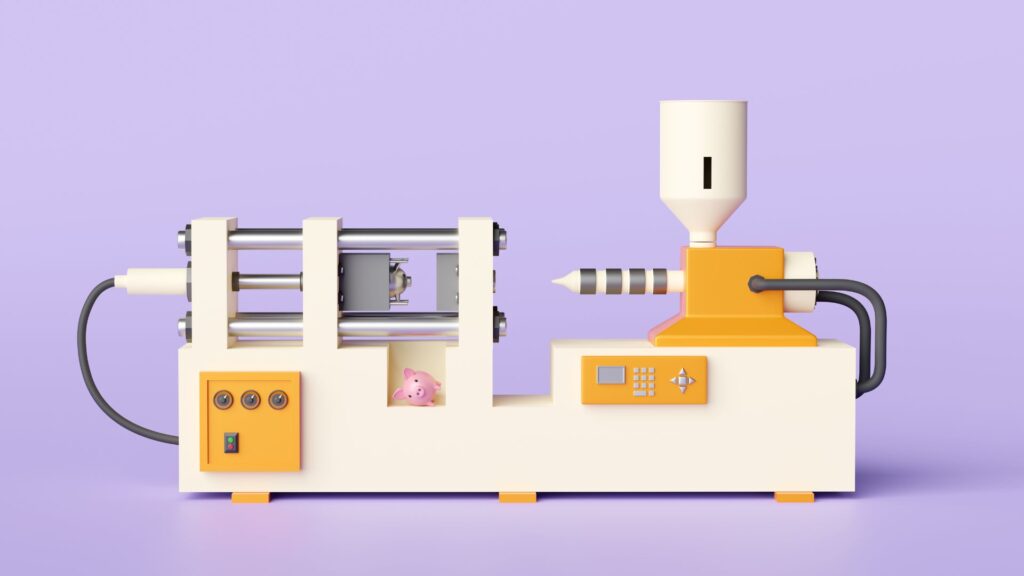

A Brief Look at the Rotomolding Process

The rotomolding process is a multi-step process that involves the following steps:

- Mold Creation

The first step in the rotomolding process is the creation of a mold. The mold is typically made of aluminum or steel and is created using computer-aided design (CAD) software. The mold is designed to be hollow, so that the plastic can be poured inside and take the shape of the mold. - Material Preparation

The next step in the process is material preparation. Rotomolding typically involves the use of polyethylene, which is a thermoplastic material that can be melted and molded. The polyethylene is ground into small pellets and then placed into a hopper, which feeds the material into the mold. - Loading

Once the mold is created and the material is prepared, the mold is loaded into the rotomolding machine. The machine typically consists of a large oven that heats the mold and a rotating arm that holds the mold in place. - Heating

The mold is heated in the oven until it reaches the appropriate temperature. The temperature will depend on the specific type of polyethylene being used and the size and shape of the mold. - Cooling

Once the mold is heated, it is rotated around the arm of the machine. This rotation helps to evenly distribute the melted plastic and create a uniform thickness in the final product. As the mold rotates, it is cooled with water or air to help solidify the plastic. - Unloading

After the plastic has cooled and solidified, the mold is removed from the machine and the finished product is extracted. The excess plastic, known as flash, is trimmed off and the finished product is inspected for quality.

Advantages of Rotomolding

There are several advantages to using the rotomolding process to create plastic products. To begin with rotomolding molds are typically less expensive than other types of molds, such as injection molds. This is because rotomolding molds can be made from aluminum or steel, which are less expensive materials than the materials used to make injection molds.

Next, there is a great deal of design flexibility. The molds can be created in almost any shape or size, and the process can accommodate complex designs with multiple parts.

When considering the end-product, items made from the rotomold process are extremely durable and can withstand a wide range of temperatures and environmental conditions. This makes them ideal for use in outdoor settings, such as in the construction and agriculture industries. Additionally, the products are lightweight. This makes them suitable for use in applications where weight is a concern, such as in the automotive and aerospace industries.

Lastly, this manufacturing process ensures that the plastic is evenly distributed throughout the mold, which creates a uniform wall thickness in the final product. This helps to ensure that the product is strong and durable. For more on the benefits of rotomolding, check out our recent article on the topic.

What is the Best Plastic for Rotomolding? Polyethylene.

As mentioned previously, polyethylene is a commonly used material in rotomolding, and it offers several advantages for this particular manufacturing process:

- Design Flexibility:

- Polyethylene can be easily molded into various forms, making it suitable for products with diverse designs.

- Uniform Wall Thickness:

- As a plastic resin, polyethylene can be evenly distributed within the mold during the rotation process, resulting in products with consistent wall thickness. This is important for structural integrity and product performance.

- Impact Resistance:

- Known for its toughness and impact resistance, polyethylene is suitable for applications where the final product may be subject to rough handling or impacts.

- Chemical Resistance:

- For applications where the end product may have contact with a corrosive substance, polyethylene exhibits excellent chemical resistance. This property is particularly valuable in industries such as agriculture, where chemical fertilizers and pesticides are commonly used. Products made from polyethylene can resist degradation and maintain their structural integrity even when exposed to various chemicals.

- Durability:

- One of the key advantages of polyethylene in rotomolding applications is its exceptional durability and impact resistance. Products manufactured using polyethylene are known for their toughness and ability to withstand harsh environmental conditions. This makes polyethylene ideal for producing products that need to endure rough handling, outdoor exposure, or extreme temperature variations.

- UV Resistance & Stability:

- Many outdoor applications require materials that can withstand prolonged exposure to sunlight. Polyethylene possesses inherent UV stability, ensuring that products manufactured through rotomolding retain their color and structural integrity over extended periods of outdoor use. This UV resistance is a valuable characteristic for products like playground equipment, water tanks, and outdoor furniture.

- Cost-Effectiveness:

- A cost-effective material for rotomolding, polyethylene fits the budget. It is readily available in the market from companies who distribute plastic resin pellets, making it an economical choice for manufacturers. Additionally, the rotomolding process itself is efficient, with minimal waste, as excess material can be easily reclaimed and reused. The combination of affordable raw materials and efficient manufacturing processes makes polyethylene a financially attractive option for various industries.

- Ease of Recycling:

- When considering the option to recycle, polyethylene contributes to sustainable and environmentally friendly manufacturing practices. The ease of recycling can be an important consideration in industries and regions with a focus on sustainability.

Polyethylene’s advantages in rotomolding include design flexibility, uniform wall thickness, impact and chemical resistance, durability, UV resistance, cost-effectiveness, recyclability, lightweight properties, and corrosion resistance. These characteristics make it a popular choice for a wide range of applications in various industries.

In summary, rotomolding is a unique manufacturing method that offers numerous advantages, making it an attractive choice for producing items ranging from storage tanks and containers to playground equipment and automotive components.